Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Development of a Mobile Liquified Petroleum (MLP) Gas Leakage Alert System with Multilingual Notifications

Authors: Uwadia Oluwafemi Anthony, Di Nrei Alan-Lodam

DOI Link: https://doi.org/10.22214/ijraset.2024.64302

Certificate: View Certificate

Abstract

This project outlines the design and development of a Mobile Liquefied Petroleum (MLP) Gas Leakage Detection and Alert System with multilingual notifications for enhanced safety in an environment using Liquefied Petroleum Gas (LPG). The system continuously monitors LPG concentrations via an MQ-2 gas sensor and, upon detecting a leak, sends real-time alerts to users\' mobile phones. Notifications are delivered in multiple languages, including English, Yoruba, Hausa, Igbo, and Berom(native language), making the system accessible to a diverse audience. The system features an ESP8266 microcontroller for gas level monitoring, with alerts displayed on an LCD and transmitted to a cloud platform for remote monitoring. It provides visual and audible warnings when gas levels exceed 550Parts Per Million (PPM), ensuring user safety. Key innovations include portability, low power consumption, and multilingual capability, ensuring quick and inclusive responses to gas leaks, with an average response time of 2.95 seconds. The system is cost-effective, user-friendly, and scalable for large-scale adoption in residential and industrial settings.

Introduction

I. INTRODUCTION

Liquid petroleum is a widely used combustible material used by all sectors of the world. LPG has become a daily need for home and commercial cooking. LPG has flammable hydrocarbons, mainly propane (C3H8) and butane (C4H10). Exposure to LPG gas can lead to health issues and may cause death. On the other hand, the accidental explosion of a gas leak leads to fires, causing injuries, fatalities, and property damage [1].

Gas leakage might occur due to faulty gas pipelines, cooking stoves, or other unintended conditions or accidents. Gas leakage is detected quickly since the gas concentration increases considerably before ignition. LPG leakage, in particular, poses a nuisance and hazard risk due to its high flammability. To avoid such hazardous occurrences, the detection of LPG has become crucial and a need of the hour. Developing a gas leakage detection system is essential to eliminate the threat caused by LPG gas. Present social needs emphasize the mandatory adoption of safety systems, appliances, and equipment that comply with regulations to keep organizations safe. In the industry, gas leakage is a major safety concern that can result in explosions, fires, human casualties, and property loss. Safety measures against LPG leakage are needed in all areas where LPG is used as fuel, and when the leakage of LPG at a certain concentration is sensed, the LPG gas leakage detection system alerts people around. The accidents caused by LPG have posed a great threat to human life and property throughout the world, so there is a need for a gas detection system to safeguard lives and property. The gas detection system is designed using a sensor to detect gas leakage and alert nearby people in danger at an early stage. All possible actions and alerts are carried out once the leakage is detected within the proximity range. When the gas leakage is detected, the system notifies the user using the buzzer. At the same time, the alert is transmitted to the mobile application, which enables simultaneous notifications in different languages (English, Yoruba, Hausa, Igbo, and Berom).

The proposed paper aims to design and develop an efficient LPG detection and alert system.

II. LITERATURE REVIEW

LPG detection involves using gas detectors to monitor and indicate the concentration of LPG in the air, aiming to prevent toxic exposure and fire hazards in domestic and industrial environments. Gas detection systems with wireless features eliminate cable wiring and offer flexibility by allowing gas detectors to be easily relocated based on changing hazards or leak sources. This adaptability enhances safety and efficiency while reducing installation costs and time, making them ideal for dynamic industrial environments.

Gas sensors, such as the MQ-2 gas sensor, are commonly used to detect LPG, with a high sensitivity and quick response time, enabling the detection of LPG concentrations in the range of 200 - 10,000 PPM.

Due to the setbacks of the wired controller, the wireless controllers offer better monitoring and resource management. The MQ-2 sensor is suitable for detecting various gases, including H2, LPG, CH4, CO, Alcohol, Smoke, or Propane [2].

A. Review of Related Works

Various research has been done on LPG systems, many of which are not mobile or are too complicated, such as the work of [3], which focused on a portable gas detection system. While their solution was simple and portable, it was limited to warning users only when online.

In [4], a gas leakage detection and alarming system was developed using the Blynk platform to detect gas leaks and send notifications to a mobile phone, the readings of which were on the gas sensor. The device also provides email notifications and data visualization for clients. Their device has a buzzer that sounds an alarm but cannot provide multilingual notifications to make it locally accessible.

In [5], the authors used a NodeMCU ESP8266 and MQ-2 sensor to detect the presence of propane, butane, and LPG and determine the concentration of this and send it to the microcontroller, which then sends the readings to the mobile app to monitor the level of gas in the atmosphere and the case gas is detected, an SMS message is sent as an alert to the user.

In [6], a gas detection system was developed that sends SMS alerts to individuals or family members when a leak has been detected. The system also measures the weight of the LPG cylinder, alerting the users when the weight is less than 10 kg and automatically booking an appointment for a refuel.

In another study [7], the authors implanted and tested a gas leakage detection and alerting system using Arduino UNO. The system used Arduino UNO (Atmega-328) as the main unit with MQ-2, MQ-7, and MQ-135 sensors and an LCD, Buzzer, and GSM Module. The system had multiple sensors installed in different places to detect gas leaks and tell them apart by displaying a message like “GAS DETECTED AT ZONE 1.”

In [8], the project incorporated an Arduino Uno Board, MQ-5 sensor, LCD, LEDs, buzzer, and jumper wires, and a gas leakage detection system with an alarming system was implemented. When gas is detected, it triggers the red LED to light up, and the LCD displays the message “Gas leakage detected,” after which an exhaust fan is activated to draw the gas away.

In [9], the researcher developed a system capable of measuring gas concentrations in PPM and the percentage of gas concentration to protect the human body from toxic gases, hazardous elements, chemicals, or compounds in the atmosphere. In their proposed system, they used an MQ-2 gas sensor, nRF24L01Plus Wireless Transceiver Module, and Arduino Uno R3, and the results were monitored at the receiver side using Arduino IDE serial monitoring.

In [10], the authors proposed an IoT-based gas detection prototype using the Proteus design suite. Their work depended on the Blink IoT platform for data visualization. They conclude that the proposed technique wirelessly transfers alert notifications to the user.

The widespread use of gas-powered systems in residences and commercial buildings has considerably raised the risk of gas leaks in recent years, endangering both lives and property. Despite efforts to solve this issue, there is a noticeable shortage of user-friendly, real-time gas detection solutions that are rechargeable and do not require constant power sources.

The reviewed works show that existing Liquefied Petroleum Gas (LPG) detection and alarm systems have several drawbacks, such as system immobility, communication problems, and continuous power, which reduces their adaptability and user-friendliness.

There is a need to create a portable system that runs off of power outlets and a gas detection system with an easy-to-use interface for seamless real-time monitoring.

In this paper, the gas detection system is designed using a sensor to detect gas leakage and alert nearby people in danger at an early stage. All possible actions and alerts are carried out once the leakage is detected within the proximity.

???????B. Proposed System Components Required

In this research, these components facilitate the construction and implementation of the mobile LPG gas leakage system with NODEMCU microcontroller.

- MQ-2 Sensor

- Buzzer

- Vero board

- Blue LCD 16x2

a) MQ-2 Gas Sensor

This paper employs MQ-2 gas sensors (as shown in Figure 1) to detect any petroleum gas leakages at home and wirelessly alert users. The MQ-2 gas sensor is widely used in various applications for detecting gases and monitoring air quality, monitoring air quality detecting gas leakages, and ensuring the safety of users and the environment. Furthermore, it can detect gases like carbon monoxide, propane, Hydrogen, methane and smoke. MQ-2 gas sensor operates on the principle of chemical reactions between the target gas and the sensor's sensitive layer. The MQ-2 Gas Sensor Module continuously monitors indoor air quality and early fire detection, displaying values on an LCD and the Blynk IoT platform, and alerts mobile phones when safe levels are breached by sending notifications in English, Yoruba, Hausa, Igbo, and Berom. In addition, users can monitor the gas levels in real-time anywhere in the designed application.

b) SFM-10B active buzzer

A beeper or buzzer (as shown in Figure 2) is a device that converts electrical signals into sound, typically powered by DC voltage. Depending on its design, it can produce a range of sounds, including alarms and music.

c) Veroboard

A Veroboard (Figure 3), also called a stripboard, is a pre-assembled circuit board used to build electronic circuits without requiring custom-printed circuit boards. It consists of a grid of holes with strips of copper on one side, allowing for easy soldering and connection of components.

d) 16X2 Blue LCD

A 16x2 Blue LCD (as shown in figure 4) is a display module featuring sixteen (16) columns and two (2) rows, allowing it to show up to 32 characters at a time. Its blue backlight provides high contrast and visibility, making it ideal for applications requiring clear, easy-to-read text output.

Fig. 1: MQ-2 Sensor Fig. 2: SFM-10B active buzzer Fig. 3: Veroboard Fig. 4: 16x2 Blue LCD

Other components are ESP8266 microcontroller, 3.3V/5V MB102 Breadboard Power Supply Module, two 3.3V batteries connected in series

III. METHODOLOGY

This paper develops and evaluates the performance of a MLP gas leakage detection system designed with the ESP8266 NodeMCU Module, focusing on sensor response time and multilingual notifications. The system utilizes a buzzer and push notifications via email and app in English, Yoruba, Hausa, Igbo, and Berom to communicate with users. This paper aims to develop an Internet of Things (IoT)-connected gas leak detector using the ESP8266 NodeMCU Module. In addition, a web and mobile application was developed to monitor and detect gas leaks in real time. The Wi-Fi and IoT technology broadcast leak alerts to stakeholders, enabling continuous environmental monitoring and direct device communication without human intervention. The system is being monitored using the Blynk application.

The multicasting of message broadcasts for alarms is another feature of this study. The system is portable with the design structure, making it deployable in any environment.

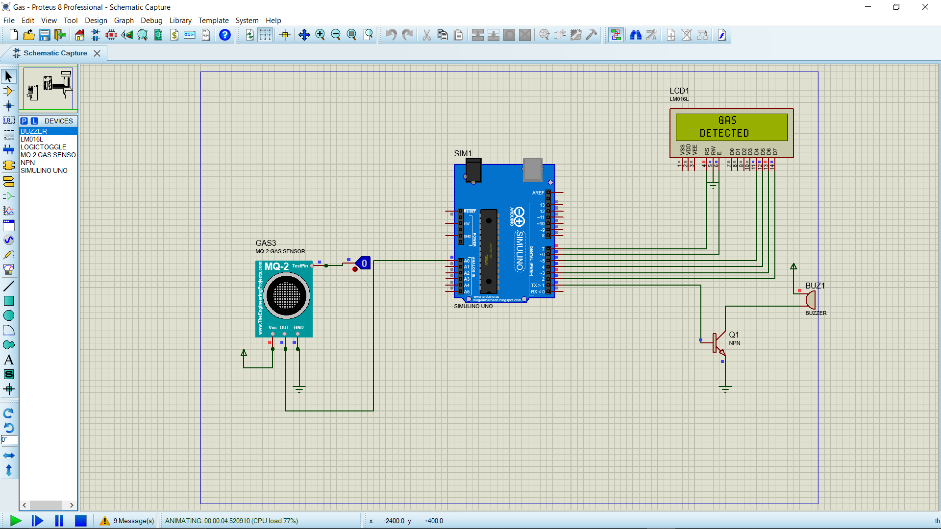

A. Circuit Diagram of the Mobile Liquefied Petroleum Gas Alert System

The Mobile LPG Alert System circuit diagram (figure 5) interfaces the MQ-2 sensor with the ESP8266 with the LED and buzzer.

.

Fig. 5: Circuit diagram of the Mobile LPG Alert System

In this paper, a threshold value of 550PPM for gas detection triggers a notification on the mobile device when this value is exceeded. The MQ-2 sensor, used for detecting combustible gases, generates a voltage signal corresponding to the gas concentration in the atmosphere; a high gas concentration results in a high output voltage, and a low concentration results in a low output voltage. This work utilizes a 550mV threshold sensor with a 5V trigger for smoke/gas level alerts.

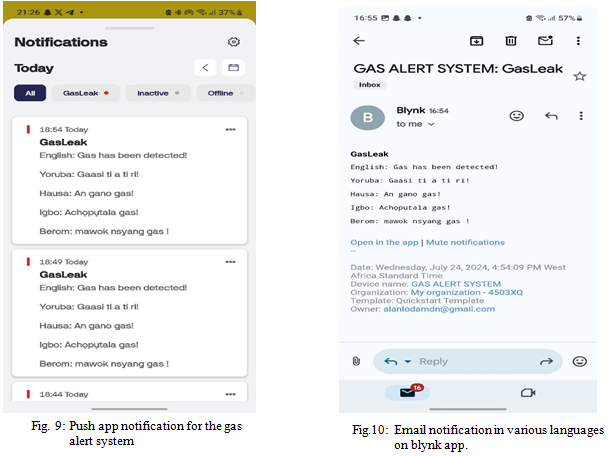

When the MQ-2 sensor detects a gas leak, data is sent to the ESP8266 controller through its analog port, as shown in Fig. 4. The ESP8266 connects to the internet and continuously monitors gas levels using the MQ-2 sensor. If the gas concentration exceeds the threshold, the ESP8266 controller will send a warning text message "Gas has been detected" in English, Yoruba, Hausa, Igbo, and Berom, as depicted in Figure 6b, alerting the occurrence of a gas leak via Wi-Fi, the ESP8266 controller uses the Blynk application, compatible with both Android and iOS operating systems. The proposed system used the IOS Blynk App. At the same time, the buzzer will be on for an alarm by connecting it to the microcontroller digital port. In the case of normal gas levels, the system displays the current gas concentration and deactivates the buzzer. The flowchart of the proposed system is shown in Fig. (6).

The embedded development board enables the concept of real-time monitoring. This development board takes inputs from the LPG gas sensor and compares it with the accepted concentration norm from the set threshold. Suppose the LPG gas concentration level exceeds the threshold. In that case, it executes all responses: sound alarm using the installed buzzer and email notification with an additional message in a different language.

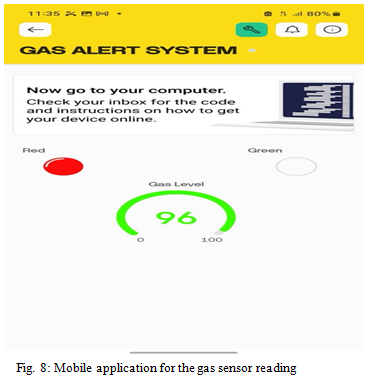

The Blynk application monitors the gas level in real time, which makes it accessible to authorized users. The gas level is monitored using the Blynk application.

Fig. 6: Flowchart for detection of gas

IV. RESULT AND DISCUSSION

Table 1 presents the test of response time for the Gas Sensor and the simulation Test result.

Table 1: Response Time for the Gas sensor

|

Test |

Response Time in second(s) |

Gas Level(%) |

Distance from the Gas cylinder(m) |

|

1 |

2.69 |

65 |

50 |

|

2 |

3.05 |

69 |

100 |

|

3 |

3.23 |

74 |

150 |

|

4 |

3.69 |

76 |

200 |

|

5 |

4.07 |

79 |

250 |

|

6 |

4.10 |

82 |

300 |

|

7 |

4.11 |

84 |

250 |

|

8 |

4.80 |

94 |

400 |

|

9 |

5.09 |

100 |

450 |

|

10 |

5.21 |

100 |

500 |

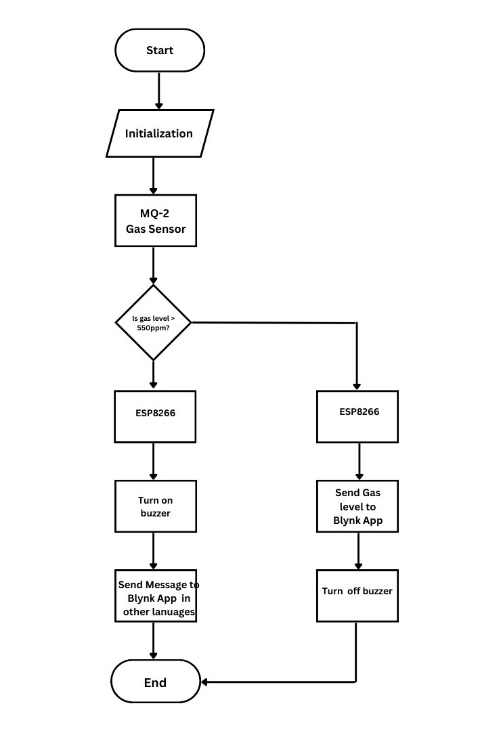

As mentioned in previous sections, this system is built based on the controller (ESP8266) with the gas sensor (MQ- 2), as shown in the real pictures illustrated in Fig. (7a) and (7b). The amount of gas, which is the gas sensor reading, can be seen in Fig. 8. In the event of gas leakage, that is, the gas level exceeds the threshold of 550PPM, the sensor will send a signal to the controller, through Wi-Fi technology, and the controller will send a message of the presence of gas leakage using the Blynk application available on the mobile phone system. In this system, an IoS mobile phone is used, and the message “Gas detected” is displayed on the device, as shown in Fig. (7b). Simultaneously, a warning message will be sent to the mobile phone interface with the Blynk app. Notification and email notification as “Gas has been detected’ in English, Yoruba, Igbo and Berom, as shown in Fig. 9 and Fig. 10, respectively.

???????A. Benefits of the system

- This system allows for the real-time monitoring of gas levels, reducing the risk of accidents and improving the overall safety of people and property.

- Notification alerts and an audible buzzer ensure that both users within and outside the premises are promptly notified in the case of an emergency.

- Users can monitor the gas levels of where the device has been placed, providing assurance of safety and allowing for quick action if needed.

- The system can easily be moved anywhere to monitor gas readings as it is mobile.

- The system can be deployed in a local environment to ensure accessibility and comprehension of any user since the alert is displayed in multiple languages (English, Yoruba, Hausa, Igbo, and Berom)

- The system is cost-effective, portable, and affordable, making it suitable for various environments, including homes, commercial kitchens, small-scale businesses, and industrial settings.?

Conclusion

This research describes an IoT approach for LPG gas detection and alert system capable of effectively monitoring and detecting gas leaks. The leakage is detected using the MQ-2 gas sensor as an input device. Then, the sensor sends a signal to the ESP2866 NodeMCU microcontroller, the central processing unit that sends signals to connected devices. The efficiency of the NodeMCU is proven through sending multiple messages to the Blynk application, which could be a message per second. The number of warning messages sent could be set by changing the programming of the NodeMCU. Using the NodeMCU microcontroller also makes the system cheaper. Quick access and control make the system very useful. The system is both user-friendly and cost-efficient, making it accessible and affordable for a range of users. Its portability allows it to be placed anywhere, providing flexibility in various environments. Additionally, the system sends notifications and alerts in multiple languages, including English, Yoruba, Hausa, Igbo, and Berom, ensuring accessibility for diverse users. The paper contributes to the broader goal of using technology to improve safety across different domains and regions.

References

[1] Malik, A., Shah, N., and Khan, R. Safety concerns and risks associated with Liquefied Petroleum Gas (LPG). Journal of Energy and Safety, 2021, Vol. 15(2), pp. 34-45 [2] Trisnawan, I. K. N., Nugroho, A., Istiqomah, N., and Wasisto, I. Detection of gas leaks using the MQ-2 gas sensor on the autonomous mobile sensor. 2019 [3] Turan, H., Y?lmaz, M., and Kaya, ?. (2019). Design and implementation of a portable gas detection system. Journal of Gas Safety and Technology, vol. 12, issue 3, pp. 45-56. [4] Jumaa, N., Abdulkhaleq, Y., Nadhim, M., and Abbas, T. IoT Based Gas Leakage Detection and Alarming System using Blynk platforms.Iraqi Journal for Electrical and Electronic Engineering, 2022, vol.18(1), pp. 64-70 [5] Ayeni, J. K. and Akinola, S. O. IoT-based gas and smoke detection system using the Blynk application with automatic SMS and alarm notifications1. University of Ibadan Journal of Science and Logics in ICT Research (UIJSLICTR), 2024, vol. 11(2), pp. 98-105. [6] Nkemeni, V., Mieyeville, F., & Tsafack, P. A distributed computing solution based on a distributed Kalman filter for leak detection in WSN-based water pipeline monitoring. Sensors, 2020, vol. 20(18), pp. 5204. [7] Shahewaz, S. B., and Prasad, C. R. Gas leakage detection and alerting system using Arduino Uno. Global Journal of Engineering and Technology Advances, 2020, vol 5(3), pp. 29-35. [8] Baballe, M. A., & Bello, M. I. Gas leakage detection system with alarming system. Review of Computer Engineering Research, 2022, vol. 9(1), pp. 30-43. [9] Mobasshir Mahbub Toxic and hazardous gas detection, measurement and monitoring system for safety assurance in home and industrial application of wireless sensor node, Engineering and Technology Research, 2019, vol. 1(3) [10] Guru rama gayathri and Yoga ananth,. IoT BASED GAS MONITORING SYSTEM USING ARDUINO, International Research Journal of Engineering and Technology, (2020). Vol. 7(4).

Copyright

Copyright © 2024 Uwadia Oluwafemi Anthony, Di Nrei Alan-Lodam. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET64302

Publish Date : 2024-09-22

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online